Construction Schedule Expert - Schedule Analysis Expert

Construction Scheduling Expert / Construction Schedule Analysis Expert Philadelphia / Main Line area of Philadelphia Office

Construction Scheduling Experts

While working on construction defect and schedule delay matters, I find myself using different phrases when discussing the extremely expensive nature of these matters. A basic Google search generally turns up interesting hypotheses of the origins of these phrases. In one example, “pay through the nose” is hypothesized to have come from ninth century Ireland, when an excessive “Nose Tax” was imposed on each nose in Ireland. What? Or in the case of “pound of flesh”, I’d not have guessed the origin to have been William Shakespeare’s “Merchant of Venice” in 1596.

It’s amazing how these phrases existed over centuries and are still used today, mostly without the user knowing the origin (at least as is the case in my case). I think it’s because these phrases are so extreme sounding. I also think that’s why these phrases come to mind when discussing construction delays and that someone, somewhere, has to “pay through the nose” or is costing someone a “pound of flesh.” As such, it’s imperative to determine what caused these defects and delays!

In a typical construction schedule delay / delay analysis, it is important to first understand what delays and defects occurred on the project. This requires a careful examination of project documents and schedules, which is typically performed by a schedule delay expert who can also ascertain which party or parties caused the defects and corresponding delays. Typical project delays result from design and engineering defects, poor project and site management, construction errors and omissions, contract issues, miscommunications and the like. Once the delays are properly identified, the delays are quantified typically in Calander Days (CDs) and further developed into damages in dollars (not “pounds of flesh”).

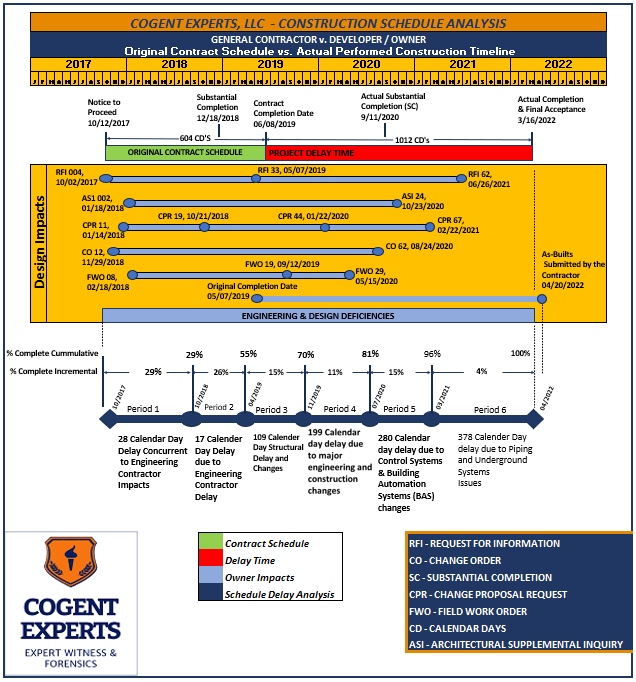

The “Construction Schedule Timeline” image of the previous page is a summary graphic for a typical commercial / industrial construction schedule analysis, and compares the planned project schedule with the actual project schedule as performed. Overall, this project ran 1012 Calander Days (CDs) over the original project timeline of 604 CDs. Ouch. Someone’s paying “through the nose” for that!

Further, the “Design Impacts” section of the chart above illustrates the design deficiencies causing the schedule delays. It is important to note not only the volume of the impacts, but when they occurred when looking at the design impacts. The dark blue summary line of the schedule analysis at the bottom of the chart, illustrates percent complete as certified payments (pay applications) for each period of the project. Interestingly, the project was approximately 75% complete through 2019, yet almost 1/2 of the project impacts issued after this time.

In this example, it is of note that “piping and underground systems” it is listed as a schedule impact because the buildings could not be occupied until a functional underground system was completed. Further, although the GC was 95+% complete in April 2021, the owner refused to accept the building knowing they could not operate without completed functional underground systems. This delay forced the owner to continue paying utilities and overhead costs until March of 2022. While not a “pound of flesh,” these costs are very expensive considering the cost of operating a non-functioning building! Connect with a Cogent resource for your construction schedule expert in Philadelphia, Baltimore, Washington DC, New Jersey, New York, Texas, Chicago or Boston needs.

In review of many construction defects and construction claims, it is clear that the use of schedule analysis, risk management methods and other protocols can create less engineering and construction defects on projects. In today’s project engineering world, be sure to manage construction schedules appropriately!

While schedule analyses techniques as described herein may be high-level in nature, they are important aspects regarding project schedule management. Should failure occur in these managerial aspects of project schedules, the resulting problems in can lead to widespread issues further increasing project cost and risk.